A combine or combine harvester is a large vehicle to harvest various grain crops. This vehicle has many uses, mostly reaping, winnowing, gathering, and threshing.

Additionally, all four processes are combined, making it easier for people to complete their work.

This can be amazing as you can work efficiently while saving time. Although, there are several other things that you need to keep in mind. Most of the features on your combine depend on the model you have bought.

You must get a vehicle like the Case IH 7010 Combine. The model is one of the best ones you can get, but there are also some problems you can run into.

How to Resolve Case IH 7010 Combine Problems?

- Feeding Issues

The throat of your feeder should always be narrow enough that it can efficiently run through crops. A wider throat can cause the slats to start touching crops, making their ends catch them.

This can be quite annoying as all the gathered material will move to the back of your vehicle. This gets stuck inside the feeder chain, plugs and blocks it.

Considering this, you can usually keep the throat narrow enough to avoid the problem. However, if you still need to and your plugs are now clogged, you can quickly clear them by stopping the vehicle.

Ensure you remove the crops properly before starting your combine harvester again. The chain on your feeder is another essential part you must check.

By default, there should be two chains that spin at different speeds. The top one is always faster than the bottom one.

Keeping this in mind, you can stop your harvester and check if the chains are not moving as they should. Ensure you keep them lubricated at all times to ensure the chains move as they should.

The chains will also be connected to a trap that opens up whenever it gathers materials. Checking the rate at which the mouth opens is also essential.

This is because the trap opening can constantly cause air to leak from the section used for cleaning. You can easily tune the rate at which the trap opens by adjusting the chains on your feeder.

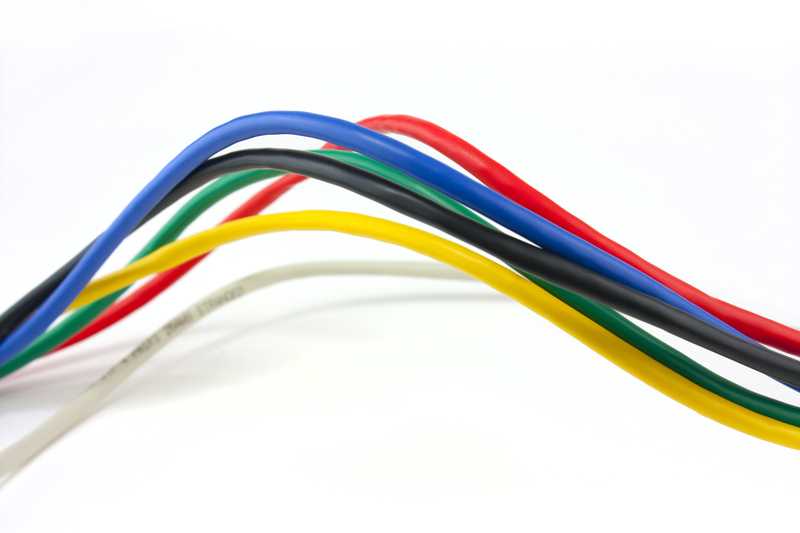

- Wiring Harness Goes Bad

The wiring harness on the Case IH 7010 combine can go wrong, causing all sorts of problems. This is especially true if the combine is used in dusty conditions.

The dust can get into the electrical connectors and cause them to corrode. When this happens, the wires can break and cause many problems.

To fix this problem, the wiring harness needs to be replaced. This is relatively easy, but a qualified technician should do it.

- Air Filter gets Clogged.

The air filter of the Case IH 7010 Combine can get clogged easily, which can result in decreased performance.

To prevent this from happening, it is essential to check and clean the air filter regularly.

The correct way of cleaning the air filter is to remove it from the combine and then use a brush or compressed air to unclog it. Once the filter is clean, you can reattach it to the combine.

- The fuel Filter gets Clogged.

The fuel filter of the Case IH 7010 Combine can also get clogged easily, which can result in decreased performance.

To prevent this from happening, it is vital to check and clean the fuel filter regularly. Once the filter is clean, you can reattach it to the combine.

- Overheating

The Case IH 7010 combine is prone to overheating, mainly when working in hot climates or when the crop harvested is dry.

The problem can be exacerbated by a build-up of dust and trash around the engine, which acts as insulation and prevents heat from dissipating.

To prevent the combine from overheating, keeping the engine clean and free of debris is essential.

- Clogging

The Case IH 7010 combine is also prone to clogging, mainly when harvesting high-yielding crops such as corn.

The problem can be exacerbated by a build-up of crop residue in the feeder house or on the concaves. To prevent the combine from clogging, it is essential to clean the feeder house and concaves regularly.

- Auger Chain Breaks

One of the most common problems with Case IH 7010 combined is that the auger chain breaks.

The auger is responsible for moving the grain from the combine’s hopper to the elevator; if the chain breaks, the grain will not move properly. You may also notice that the auger should be turning slower than it should be.

Another common problem with Case IH 7010 combine is that the straw walkers break.

The straw walkers are responsible for moving the straw from the thresher to the baler; if they break, the straw will not move properly. You may also notice that the straw should move slower than it is.

If you are having problems with your Case IH 7010 combine, you must take it to a qualified mechanic or dealer for service. Remember not to attempt to repair the combine yourself, as this could void your warranty.

- Engine Problems

Another common issue people report about getting on a Case IH 7010 Combine is that its engine starts running into problems.

You can quickly identify this by keeping a check on the sound and performance of this part. Stop your vehicle if you notice any odd sounds from the engine or if the harvester is having trouble performing.

There is a high chance that something might be wrong with your vehicle, which can cause a problem like this. Some things that you can check include the coolant tank on your engine as well as its engine oil.

The coolant has to be filled up after some time, and you have to ensure that it remains filled. This liquid is responsible for preventing your engine from overheating.

On the other hand, you can check the state of the engine oil in your vehicle and confirm if it has gotten old.

Thick and dark-colored engine oil should be replaced as soon as possible to preserve the health of your engine.

- Shaker Driver Belt Comes Off

The shaker driver belt on the Case IH 7010 combine can come off when the combine is under a heavy load.

This can cause the shaker to stop working and damage the shaft. You will need to replace the shaker driver belt to fix this problem.

- Hydraulic Pump Leaks

The hydraulic pump on the Case IH 7010 combine can leak oil, which can cause the hydraulic system to lose pressure.

This can lead to problems with the combine’s ability to raise and lower the header. To fix this problem, you will need to replace the hydraulic pump.

However, if it’s a minor glitch, it could just be a gasket or O-ring that needs to be replaced.

- Engine Oil Leaks

The engine oil on the Case IH 7010 combine can leak, which can cause the engine to overheat. This can lead to engine damage.

Consider replacing the oil seals and gaskets to fix this problem. However, if it’s a small leak, you may be able to tighten the bolts that hold the oil pan in place.

- Header Lifts Slowly

The header on the Case IH 7010 combine can lift slowly, which can be frustrating when trying to get the job done quickly.

A hydraulic leak usually causes this problem. To fix this problem, you will need to find and fix the hydraulic leak.

- Header Lifts Quickly But Results In Low Grain Yields

One of the most common issues reported by Case IH 7010 combine owners is that the header lifts quickly, resulting in low grain yields.

Several factors, including improper header adjustment, worn-out parts, or debris build-up, lead to this.

If you’re experiencing this problem, you should first check the header height adjustment. If it’s set too low, the combine will lift the header too quickly, and grain will be lost.

If the header height is adjusted correctly and you still have issues, parts are likely worn out and need replacement.

Common parts that wear out and cause this problem include the header lift cylinders, header tilt cylinders, and header levelling cylinders.

Another possibility is that debris has built up inside the combine, causing the header to lift too quickly. This can be cleared by taking the combine to a dealer or service center for a thorough cleaning.

- Damaged Parts

Sometimes when driving the Case IH 7010 Combine, people might notice that a part stop functioning. This can be frustrating, but you should check if there are any clogged crops on the vehicle.

If there aren’t any, then you should contact the support team for Case IH.

The team will then look into your vehicle and provide you with a solution that can be used. Usually, if there are any damaged parts on the harvester, you must take it to a workshop.

The team will investigate the problem and tell you if the part can be repaired or requires a replacement.