In most situations, using a medium-frame skid steer is the safest option for contractors. These medium-frame units are quite versatile and fit the requirements of most landscaping jobs.

So, if you’re unsure about the work environments and have to go through various jobs throughout the year, then browning through some medium-frame skid setter will help you find the perfect match for your projects.

With that said, a few users have asked about the Bobcat S595 problems. If you’re interested in a similar unit and want to know more, then the following list of common issues will help you make a better purchase decision.

Bobcat S595 Problems

- Starting Problems

Even though this issue might not seem that serious at first, it can create a lot of delays in your project. So, you’ll struggle to maintain your system’s efficiency when your loader doesn’t start as you try to engage the engine.

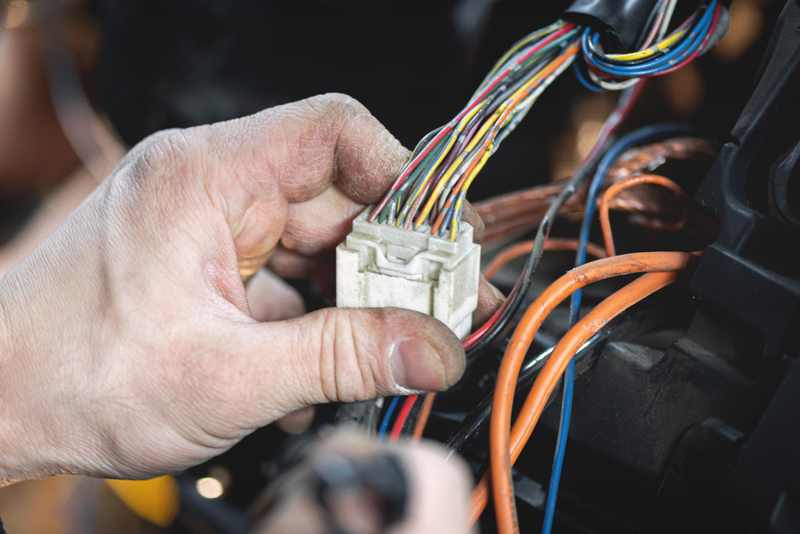

This issue with the skid steer can be traced back to issues with the wiring and the battery installed in the unit. You can further isolate the problem by using a multimeter and narrowing down the defective wires.

In most conditions, you must use a vinegar solution or any cleaner from the market to clean the connection points. Once the connection points are cleaned, you can start the engine again, and it should work without further issues.

However, if you’re dealing with kinked wires or frayed sections in the wiring cluster, you will have to replace these wires to get everything working again.

Aside from that, you should also check the power output from the battery terminals to ensure that your system is working perfectly.

If the power output is not optimal, you will have to install a new battery. Otherwise, you will keep running into this problem.

- Performance Issues

There have been a lot of complaints about the poor quality of fuel filters initially installed on the Bobcat S595.

Users mention that these filters keep getting clogged after a few days, and the only thing you can do here is to replace the filters or use high-quality fuel to get optimal performance from the engine.

However, if you’ve just replaced the filters and the engine is stalling under load, then there is a possibility that you’re dealing with clogged injectors.

Clogged injectors can be cleaned with the majority of cleaning agents from the market, and if they are in good condition, then you won’t have to take apart each component for thorough service.

On the other hand, if you haven’t serviced the unit in a long time, it might be a good idea to thoroughly clean all components linked with the injectors.

After replacing the fuel filters and cleaning the injectors, the issue with the performance of the Bobcat S595 should be fixed. However, calling customer support might be your only option if you’re still not getting the desired performance.

- Sensor Problems

Aside from the performance issues, some users have complained about the sensors not working properly in this unit. Usually, this issue is linked to defective wiring and corroded connection points.

So, there is a good chance you won’t have to purchase a new sensor, and fixing the wiring will help you avoid this issue.

You can start the inspection with the fuse in-line with the sensors. If you’re sure the fuse is in good condition, check the power output from the wires with a multimer.

As long as there is power in the wires, your wiring system is in perfect shape, and you need to replace the sensor.

However, if the power output is negligible, you must replace broken wires and clean the connection points.

All in all, these were a few issues you can expect with the Bobcat S595. If you’re stuck in a unique situation, then calling the experts working at customer support is your only option.

That way, you won’t have to spend hours in the troubleshooting process. You can also call a local expert if your unit is not under warranty. Make sure to involve professionals and don’t experiment with the electrical components.

- Low Engine Power

The Bobcat S595 skid steer loader is a powerful and reliable machine, but just like any other piece of heavy machinery, it can experience problems from time to time. One common problem experienced by operators of the Bobcat S595 is low engine power.

This issue can be caused by several factors, such as worn drive belts, air filter clogs, or even fuel injector issues.

Low engine power reduces productivity on the job site and can lead to further damage in the long run if not addressed quickly and correctly.

To fix this issue, it’s important to first identify the root cause of the low engine power. Once that is determined, repair and maintenance can be carried out accordingly.

- Heat Build Up

Another common problem experienced when operating the Bobcat S595 is heat build-up. This is usually caused by a lack of proper maintenance and can lead to engine failure if not addressed quickly.

Heat build-up can be caused by issues such as worn radiator hoses, blocked air intakes, or faulty fan blades. Heat build-up can be diagnosed and repaired fairly easily, but it is important to do so quickly to avoid further damage.

- Coolant Leaks

These leaks can be caused by issues such as loose or worn hoses, faulty gaskets, or even cracks in the radiator. Diagnosing and repairing coolant leaks as soon as possible is important to avoid further damage and costly repairs.

To diagnose this issue, begin with a visual inspection of the hoses and gaskets, then use a pressure tester to check for leaks. If any are found, they must be repaired or replaced as soon as possible.

- Hydraulic System Issues

The hydraulics system of the Bobcat S595 is known to be problematic and requires regular maintenance. If not properly maintained, it can lead to several issues, such as leaking hydraulic hoses, blown seals, leaking cylinders, and worn pumps.

Check for oil leaks or any other visible damage to identify a faulty hydraulic system.

If you observe something unusual with the hydraulic system, contact a qualified mechanic to get it checked.

8. Too Noisy

If your Bobcat S595 is too noisy, check the air filter to ensure it isn’t clogged or dirty. If it is, replace it with a clean one. Ensure all belts are properly tensioned, and the muffler and other components are free of any blockages that could restrict airflow.

You should also inspect the drive pulley for any signs of wear and tear. If necessary, replace it with a new part. Contact your local Bobcat dealer for further assistance if the noise persists after this inspection.

How to maintain the Bobcat S595 in good condition?

Maintaining the Bobcat S595 in good condition is essential for ensuring that it performs optimally. Regular maintenance and repair of the machine will help ensure its longevity, reliability, and safety.

This article outlines some key tips for maintaining a Bobcat S595 in good condition.

Checking oil levels should be done regularly, ensuring that all moving parts are kept lubricated and running smoothly. The engine oil should also be changed regularly according to the manufacturer’s recommendations.

All filters, including fuel, air, and hydraulic filters, must be replaced every 500 hours or annually, depending on usage rate.

Next, inspecting hoses and belts for signs of wear or damage is important, as they can cause major issues if left unchecked. Any worn or damaged parts should be replaced immediately with genuine OEM replacements from authorized dealerships.

These are designed specifically for the Bobcat S595 model to guarantee optimal performance and durability over time.

Always check tire pressure before each use, as incorrect pressures can significantly affect handling characteristics when operating the machine at full capacity or higher speeds over long distances.

Proper storage of the Bobcat S595 is critical for maintaining it in good condition. Store the equipment out of direct sunlight and away from any moisture or dust which may cause corrosion to parts over time.

Also, cover the machine with a tarp or plastic sheet when not in use, as this will help prevent dirt and debris from building up in the machine.

These are some key tips for maintaining a Bobcat S595 in good condition. Regular maintenance and repair of the machine will help ensure its longevity, reliability, and safety over time.

Concluding thoughts

Proper maintenance and regular servicing of the Bobcat S595 are essential for ensuring its optimal performance. This article has outlined some key tips to help maintain your machine in good condition over time.

From checking oil levels regularly to replacing filters every 500 hours or annually, you must take care of your equipment if you want it to last longer and perform better.

Additionally, inspecting hoses and belts for signs of wear or damage and storing the machine out of direct sunlight will all contribute towards keeping the Bobcat S595 running efficiently with minimal issues.