Gone are the days when farmers made small square bales and stacked them by hand. While it is still a popular method of haymaking even today, it can be troublesome and painstaking. Thankfully, there is another convenient and time-saving way to do that efficiently.

A baler is farming machinery that takes cut and raked crops and compresses them so that you can transport them easily. Not only is it convenient, but it also maintains quality.

It is seen that well-baled bales hold nutrients better, keeping them fit for later use. This makes them must-have equipment for farmers.

A baler may be used to compress hay, silage, or cotton into a solid bale. There are different kinds of balers that can be used to compress crops following different methods. So, different types of bales can be made depending on the bailer used.

All the Problems Faced by Claas Baler

Based in Germany, Class is a leading agricultural machinery manufacturing company. The company offers a wide range of machinery but is mainly known for its top-quality balers. It manufactures highly advanced and powerful balers that simplify farming.

That being said, it’s not all smooth sailing for Claas balers. Just like every farming equipment, they also show problems over time. Thankfully, most of them can be fixed easily. This article will discuss some of the most common Claas baler problems and their solutions.

- Bale Gets Wedged in

Bale getting wedged in is one of the most common problems baler users face. Many users have complained that the bale gets wedged in as soon as they are done with bailing. Of course, this situation is quite frustrating for the user as the bale they make is useless.

In order for you to fix this issue, it is recommended bail in the same direction in which you mowed. This is likely to fix the issue, but if it doesn’t, you might be missing wear plates in the back door. Check to see if that’s the case.

If so, you can easily buy these accessories at your nearby hardware store. If you do not find them there, you can also purchase them online. Many online stores offer wear plates and other Claas baler accessories.

Lastly, see if the bearings are too tight. In some cases, tight bearings also led to this problem. For this purpose, you will need to check each bearing and adjust the one which seems too tight.

- Bale Gets Wrapped Around Rubber

Another common problem that you are likely to face while using Claas balers is that sometimes, the bale gets wrapped around rubber. When starting a new roll, it is a good idea to loosen the tensioner.

The net wrap problems are quite common with Claas balers, and you will have to check whether it wraps the bale or not.

If it doesn’t, the problem might be deeper, and it is recommended to visit a mechanic. Apart from that, also take a look at the springs of your Claas baler and ensure they are working fine. If they have worn out, consider replacing them to resolve this problem.

The best way to avoid these problems in the first place is to conduct regular maintenance of your Claas baler. These balers may be efficient and all, but they also need to be serviced every now and then.

During maintenance, the mechanic will detect a problem in time, saving you from costly repairs and headaches later on.

- Knotter Issues

Knotter is one of the most important components of a baler. As its name suggests, it ties a knot to keep it all in place. Its needle pulls the twine, and the arm pushes it around the bale, allowing it to tie a knot. However, many users have stated that sometimes the knotter does not tie the knot.

Incorrect shimming is one of the important reasons for knotter issues. The twine disc will not rotate correctly if the knotter is not shimmed properly to the gear. This will result in unnecessary wear on the corner. Ultimately, this situation can lead to a broken knotter frame.

Simply slide the knotter assembly over to find out how many shims you need until the pinion is tight against your intermittent gear. If you see no play in the pinion or in the shim area, it indicates that you have the right number.

With the right number of shims, you will be able to form a snug fit. Now, put in a cotter pin a bit forcefully. Once it is secured, everything will be tight, and there will be little play in the pinion. However, the knotter can still be raised and lowered easily.

Over time, you may need to adjust the number of shims. This will be taken care of during maintenance. The twine disc pinion’s corner may also wear over time.

Taking a shim out will enable the pinion to line up at a better angle. However, make sure to add another shim on the other side to compensate. This will keep the knotter frame from breaking.

- Excessive Noise While Baling

Many users have reported that the Claas baler makes too much noise sometimes. The noise is bearable in most instances. However, it can be difficult to deal with when it reaches deafening levels.

Unfortunately, this problem is not specific to Claas balers only. It is important to point out that it usually happens in case of overuse.

Sadly, there is nothing much you can do about it. If you notice that your Claas baler has been emitting too much noise lately, it is time to see a mechanic.

They will conduct a thorough inspection and diagnose the reason. Handling repairs on your own can be dangerous. And yes, keep your hands and loose cloth away from the moving parts.

- Engine Overheating Issues

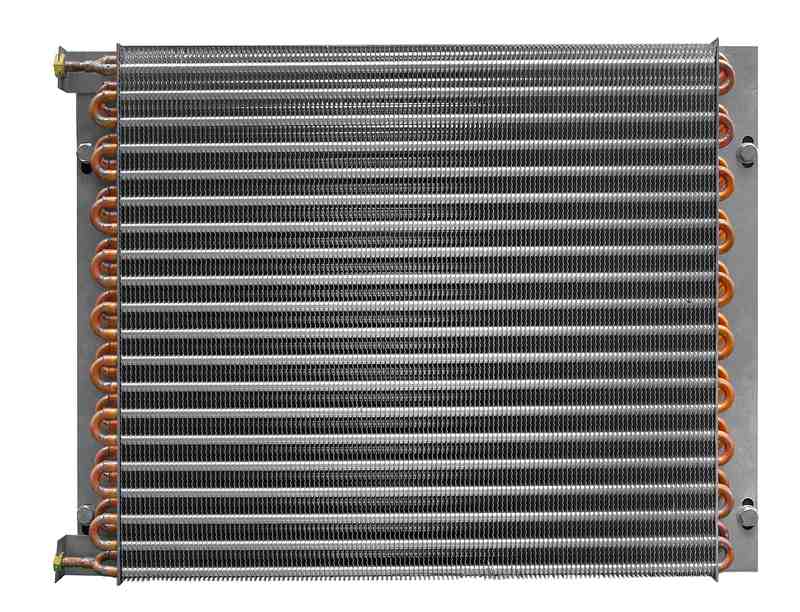

Although it is not a common problem, some users have complained about engine overheating while using Claas baler, even when they did not overuse it. If you notice that your engine is overheating, you will need to inspect your baler’s cooling system.

Start by inspecting the radiator and make sure that it is clean. The radiator is crucial to your engine cooling system as it monitors the temperature and keeps your engine from overheating. However, the radiator itself may get dirty over time, and when it does, you are likely to face engine overheating.

If the radiator of your Claas baler is dirty, consider cleaning it to remedy the overheating problem. Distilled water works fine, but it is best to use a radiator cleaner for this purpose. Aside from the radiator, a dirty air filter can also cause overheating. If so, clean it carefully, and it will fix the problem.

Final Thoughts

Baler is equipment that comes in handy when compressing and transporting cut and raked crops. Claas balers are quite popular among farmers, thanks to their superior construction and durability. However, the bale gets wedged in or wrapped around the rubber sometimes.

Knotter and noise problems are also quite common. We have discussed all the common problems and their solutions in this article. However, it is always best to hire a professional as repairing at home involves risk.