New Holland is a globally-known brand for its high-power and reliable tractors. All their tractors are designed with advanced features to ensure the farmers have a convenient experience. Every tractor is designed with unique features, and T6030 is one of the best tractors that they have designed.

Common New Holland T6030 Problems

The New Holland T6030 tractor is a popular option among gardeners and farmers, but there have been various complaints regarding the tractor’s performance.

- Lack of Power

The tractors are designed to manage heavy loads, which is why they need sufficient power. The tractor is powered through a battery, particularly the electrical components of the tractor.

So, when the tractor’s electrical components are not working, the first solution is to check the battery. If you have not changed the battery for two to three years, you need to get it replaced right away.

However, before the replace the battery, make sure you clean its terminals because the built-up dust and crust can prevent the transmission of electric signals.

You can use a contact cleaner to clean these terminals. In addition to this, make sure you inspect the wires connected to the battery, and that they aren’t damaged. This is because the wires are a transmission medium and need to be in optimal condition to ensure an uninterrupted power connection.

- Slow Hydraulic Arms

The tractor is designed with hydraulic arms, which are responsible for lowering, raising, and holding the stuff. However, when the hydraulic arms start operating slowly, it can result in slow digging and vegetation.

The hydraulic arms are connected to the main hydraulic system of the tractor, and if there is something wrong with the hydraulic system, it slows down the performance of the arms.

The most common reasons behind slow hydraulic performance are clogged filters, contamination, insufficient levels of hydraulic fluids, and higher fluid temperature.

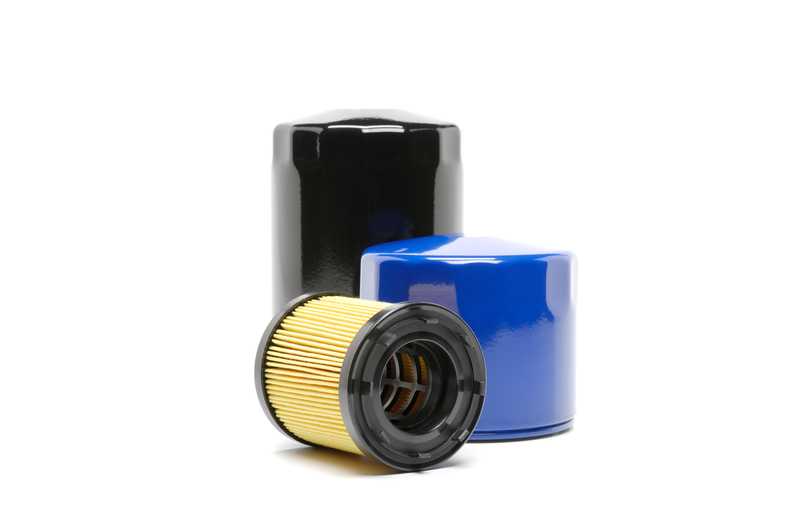

To begin with, you have to get the filters replaced because clearing the clogging is not possible as there are dust particles and grease, which are challenging to wash away.

In addition to replacing the filters, you have to check the hydraulic fluid level and make sure the reservoir is filled up to an optimum level. Lastly, there are chances that the fluid is overheated, and to solve this issue, you need to get the fluid replaced or fill up the coolant reservoir.

- Voltage Problem

Proper voltages are essential to power up the tractor and use the electrical components. However, if the voltages fluctuate, the tractor won’t operate properly.

To resolve the fluctuating voltage issue, you have to check the relays and fuses – you need to get them replaced. It is recommended that you hire a mechanic to install new relays and fuses and choose high-quality parts to ensure they work optimally.

The New Holland T6030 tractor is extremely durable and has a strong engine. However, with time, the engine’s performance takes a hit. In the majority of cases, the engine starts overheating, which reduces the overall performance of the tractor.

To optimize the optimal temperature of the engine, you have to check the coolant level and keep it at a recommended level to ensure the engine is cooled down.

Secondly, you have to check the radiator because it’s another component that cools down the engine. Usually, the radiator gets clogged, which hinders the airflow and leads to overheating.

You can hire a mechanic to clean the radiator and clear the impurities. Last but not least, you must load up the tractor within its weight capacity.

- Slow Tractor

A slow tractor is caused by damaged spark plugs. The spark plugs are essential for supplying the electric spark that ignites the air and fuel mixture, which helps the engine to produce power.

The spark plugs are extremely small but are important for creating an electric arc across the leads. However, the spark plugs can get damaged if you use the tractor regularly.

In addition to the slow performance, the damaged spark plugs can also lead to lower fuel efficiency. It is recommended that you replace the spark plugs to optimize the tractor’s speed and performance.

You must purchase high-end spark plugs to ensure they work consistently and get them installed by a professional mechanic to make sure the connections are correct.

The second thing you need to know is to check the carburetor. A carburetor is important to mix up fuel and air for operating the engine.

So, when it gets clogged, the overall performance of the tractor will be impacted, which is why you have to get the carburetor cleaned. However, if you cannot clean the carburetor, replacement is recommended.

The third reason behind a slow tractor is an issue with the fuel system. If there is something wrong with the fuel system, the performance deterioration will be slow. Usually, the fuel fails to reach the engine, resulting in slower performance.

To fix this issue, you should check the fuel control level and make sure it is not jammed. If the control level appears jammed, you should use a lubricant to smoothen its operation.

- Drained Battery

A battery is an important component of the tractor to operate different electrical and mechanical parts of the tractor. However, if you did not use the tractor for a long time, the battery will be drained out, and the tractor will fail to operate.

The solution is to charge your tractor’s battery, and it will help power the tractor. On the contrary, if the tractor doesn’t operate even after changing the battery, you need to schedule an appointment at a service department.

- Dull Blades

The tractor is integrated with huge blades that are essential to dig up the ground, level up the ground, and create paths for sowing the plant seeds. So, when the blades are dull, they won’t perform well, and the overall vegetation experience will be impacted.

It is recommended that you sharpen the blades with a file or hire a mechanic to handle the sharpening for you.

If you use the tractor daily, you should get the blades sharpened after every three months. However, twice a year is enough if you use the tractor rarely. Also, if you hire a mechanic, you can get the blades smoothened as it can prevent rough edges.

- Difficult To Handle

If your tractor is getting hard to operate, such as lag in turning, weird clunking noises, and abrupt vibrations, you must check the driveshaft. A driveshaft is responsible for transferring the engine’s torque from a gearbox to the tractor’s tires.

In addition, it can compensate for the variations in length and angle that results from improper sync between joints and constant maneuvering.

So, if you are experiencing any of these symptoms, it is suggested that you use the two-wheel-drive instead of the four-wheel-drive. However, if changing the drive doesn’t work, there are chances that the driveshaft is broken.

The only solution for a broken driveshaft is a replacement. Once the driveshaft is replaced, the tractor will start working smoothly.

- Steering Wheel Not Working

The steering wheel is responsible for changing the direction of the tires, so you can turn the tractor in different directions. New Holland T6030 tractor needs a power steering fluid to ensure smooth operations.

So, when the steering wheel doesn’t turn or is too hard to rotate, it’s because the fluid level is low. It is recommended that you check the fluid level and add more fluid. You can also hire a mechanic to fill up the steering fluid reservoir.

The Bottom Line

New Holland T6030 tractor is durable equipment for farmers as it’s powerful enough to dig up the ditches, level the grounds, and help with vegetation. However, knowing the common tractor problems can help you ensure quick troubleshooting.

As far as the repairs are concerned, you must hire a professional mechanic. On the other hand, if the tractor or its parts are in warranty, you should call New Holland’s customer support for technical assistance – it ensures that the warranty is not voided.

New holland t6030 boom mower. The arm is stuck outward in the mowing position. The hydraulics work but minimally and not enough to move the boom. Fluid levels are good, engine coolant is good.