Kubota has the most exceptional range of agriculture and gardening equipment available, including skid steers, tractors, lawn mowers, harvesters, and more. All the machinery is designed with high-tech features and high-quality components to deliver effective results.

However, the fuel pump problems are common with Kubota equipment, just like other vehicles. So, before you invest in the Kubota machinery, there are some common problems that you must be aware of.

Most Common Kubota Fuel Pump Problem

- Ticking Sound

When you turn on the engine and hear a ticking sound, it is usually caused by water in the air filters. When the machinery starts making a ticking sound, the machine will run for three to four minutes, and after that, the sound will become rougher. A wet water filter can deteriorate the Kubota machinery’s performance. In addition, if the filter stays wet, it results in engine choking.

Moreover, if the wet air filter is not replaced on time, the water can get into the engine where it mixes up with oil, which is a huge mess (it causes rusting of the engine and fuel line).

In the majority of cases, people wash the air filters and don’t dry them before reinstallation. Having said that, you must get the air filter replaced with a new one and have the mechanic clean the engine to remove moisture/water.

- Power Loss When Under Load

The Kubota machinery often starts losing power when it’s under pressure or load. It is generally caused by the vehicle not receiving enough fuel, so it’s recommended that you replenish the fuel level in the vehicle.

In addition to this, you must clean the fuel filters to make sure the fuel is properly flowing through the injectors rather than being trapped by a clogged fuel filter.

The filter helps collect the dust and dirt particles from the fuel to make sure the engine gets clean fuel. In addition, it ensures a proper pressure of fuel flow. Once the fuel flow is regulated, the fuel pump will start working properly and the engine won’t turn off, irrespective of how much load you put on it.

Lastly, always check the load or weight capacity of the machine to prevent overheating.

- Engine Getting Air Locked

The engine starts locking out the air after running for an hour or two of constant operation. In case your engine is showing a similar issue, you must get the fuel pump inspected because it’s caused by leakage and/or a hole in the fuel pump. A leakage will reduce the fuel flow’s pressure.

In addition, the low pressure of fuel will also trap air in the system. The solution is to get the fuel pump’s leak fixed and get the air removed from the system.

- Whining Noise In Fuel Tank

A loud whining sound is the most common symptom of a damaged fuel pump. This issue arises when the fuel pump is old. Usually, the fuel pump produces a humming sound (it’s normal).

However, the whining noise is the result of insufficient fuel, contaminated fuel, and a damaged pump. The first thing you need to do is to check the fuel level, and if it’s low, make sure to fill the fuel tank.

Secondly, you need to check the fuel filter. A fuel filter is responsible for cleaning the fuel to make sure the engine gets dirt and dust-free fuel. With time, these contaminants clog the fuel filter, which means the fuel’s flow will be restricted and the fuel pump’s function will be limited.

To reverse this situation, just replace the fuel filter. Last but not least, hire a mechanic to inspect the fuel pump, and if there are some damages, get them fixed.

- Clogged Fuel Injectors

The fuel injectors are designed with nozzles that spray the fuel directly into the cylinders or intake manifold. This fuel is used by the engine after combining it with air to support the combustion process. However, the combustion creates carbon deposits, which tend to clog the fuel injectors over time.

As a result, fuel injectors fail to perform and the Kubota vehicle doesn’t operate. It is recommended that you inspect the injectors, and if they seem clogged, you need to clean them.

- Clogged Fuel Lines

Fuel lines are an important part of the fuel pump, which is why discussing them is important. The fuel travels through these lines in the fuel system and can get clogged. In addition, they are prone to leaking, which can cause issues in overall performance.

For instance, it can result in an excessive flow of fuel, which ignites, damages the exhaust, and shoots flames right out of the rear pipes. In the majority of cases, the fuel lines leak or clog up when they are too old, so, get the fuel lines replaced.

- Clogged Strainer

The fuel pump is designed with a strainer on its intake port, which works as a fuel filter. The strainer is usually clogged by dirt and rust, which prevents the flow of fuel into the fuel pump.

When the strainer is clogged, the engine starts sputtering (the engine might sputter for a few minutes and return to normal operations). However, the sputtering will only increase with time.

To fix this problem, you have to inspect the strainer as well as the fuel pump; you will need to remove the fuel pump for confirming clogging in the strainer. If it’s clogged, you can opt for a portable vacuum cleaner to clean it while metal pieces can be removed by hand.

However, if the strainer is clogged beyond cleaning, it would be better to replace the strainer. Also, you should replace the strainer after every six months.

- Leaking Fuel

The fuel leaks are caused by external or internal fuel tank leaks. The fuel leaks result in low fuel pressure and stalling and jerking of the vehicle. In addition, low fuel pressure can result in overheating, which can cause permanent damage to the fuel system. To identify the leaks, you have to perform a leak-down test and an injector balance test.

To perform these tests, you will need an OBD2 scanner or an OEM scanning tool, which is why it’s best that you hire a mechanic as they have the testing equipment available.

- Fuel Pump Failure

A fuel pump is an integral part of the Kubota machinery as it’s responsible for directing fuel flow into the engine. However, if the fuel pump has failed, it’s likely that you’ve been using it at a low fuel level for a long time. There are various solutions that you can try to fix the fuel pump.

Electrical Connections

When the fuel pump is operating normally, there will be a buzzing sound when you push the ignition key in the first position. However, if you cannot hear a sound, it means that the motor isn’t getting electric input.

If this is the case, you must use a tester to check the electric connections on the fuel pump. If there is no impulse, you’ve to replace the electric connections, including the connectors.

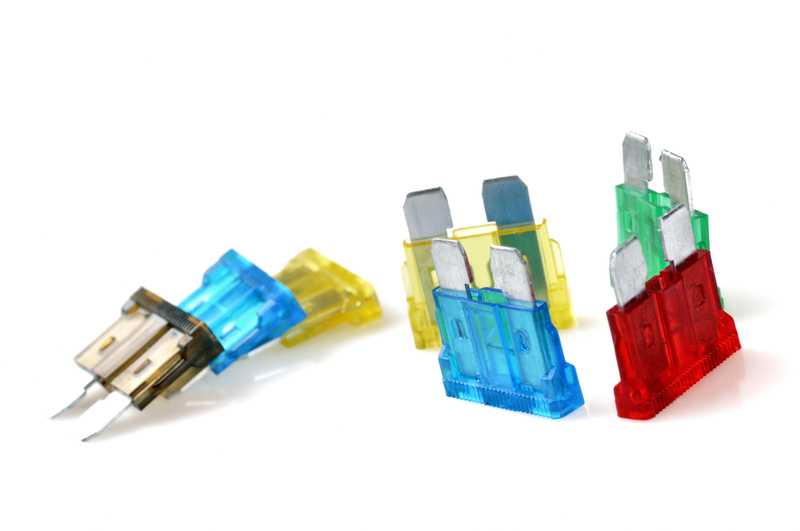

Fuse

The second thing you need to check is the fuel pump fuse. The fuse tends to burn out when there is a short circuit or overload in the machinery’s electric system.

Fortunately, fixing this problem is quite easy as you only have to replace the fuse. In addition, you must check the relay’s contacts on the contact board to make sure they are clean (it’s important for the correct transmission of electronic signals).

Seal

The last thing you need to check is the fuel pump seal, which is the rubber gasket added between the fuel tank’s ledge and the fuel pump’s housing. It is responsible for sealing the connection, but with constant material fatigue, the rubber tears down, and the sealing is damaged.

As a result, air finds its way into the fuel tank, resulting in fuel pump issues. So, just get a new seal for the fuel pump!

The Bottom Line

The fuel pumps are complex components and solving a minor issue can be time-consuming and challenging for people with zero machinery experience.

For this reason, you must seek professional help to make sure the repairs are done correctly. Last but not least, if the fuel pump is in warranty, it’s better to call Kubota for free technical assistance and repair.

Is it possible to put a reg lawn mower fuel pump instead of the one that mounts in to motor