A tractor is a much better option for large uneven patches of land. You will save a ton of money on the purchase, and the tractor won’t get stuck in ditches.

So, before putting your money into a new unit, you should always analyze the project requirements and make the final decision accordingly to avoid any extra delays in the work.

Recently many owners have been looking into John Deere 790. It is a phenomenal unit with many utility features for farmers. However, it is not unusual to run into problems with John Deere 790 now and then. So, let’s cover a few of these issues and how you can fix them quickly.

John Deere 790 Problems

- Unit Not Starting

A major issue with John Deere 790 is that it won’t start as you try to engage the system.

Luckily, the troubleshooting method is not that complicated for this issue, and you usually look at corroded connections. So, inspect the battery levels with a multimeter and then check the integrity of connection points.

In most situations, you will find that the connection points are corrupted or the battery is drained. So, you can either install a new battery in the system or fix the starting issues.

- Loader Problems

When you browse the community forums for a while, there won’t be many nice reviews regarding the front loader on this unit. The setup is not powerful enough to handle the excessive load, and you will often struggle to manage the bucket angle.

Here you can’t do much about the power issues, but as far as the loader angle is concerned, removing the bucket and then attaching it again should eliminate the problem. Refer to a mechanic if you’re unsure how to remove the loader bucket.

- Electrical Issues

As far as the electrical components and indicators are concerned, you will likely run into issues with broken wiring. There is no deficiency of complaints on defective switches and electrical parts installed in John Deere 790.

The good thing here is that you can almost eliminate all of these issues by servicing the unit once every month. That will keep the wiring in perfect condition, and you can further enhance system performance through monthly maintenance.

- Low Power

The hydraulic unit in the John Deere 790 is pretty stable, but a lack of maintenance can also create issues with low power in this unit. So, if the system is underperforming and you cannot move the desired load, then check the hydraulic fluid levels in the system.

There is a good chance that the hydraulic fluid is insufficient, and you will have to top up the reservoir to get everything working again. Once the reservoir is full, you can test the performance again, which should work perfectly.

- System Stalling

Stalling issues with the John Deere 790 can almost always be linked to the fuel supply to the engine. Either you’ll be dealing with a clogged valve, or there will be something wrong with the fuel filters. So, inspect the whole fuel system if the engine is stalling under no load.

On the other hand, if you’re putting excessive pressure on the loader, try to limit the usage, and there will be improvements in the stalling problems. You can rely on fuel stabilizers and use quality fuel to maximize engine performance.

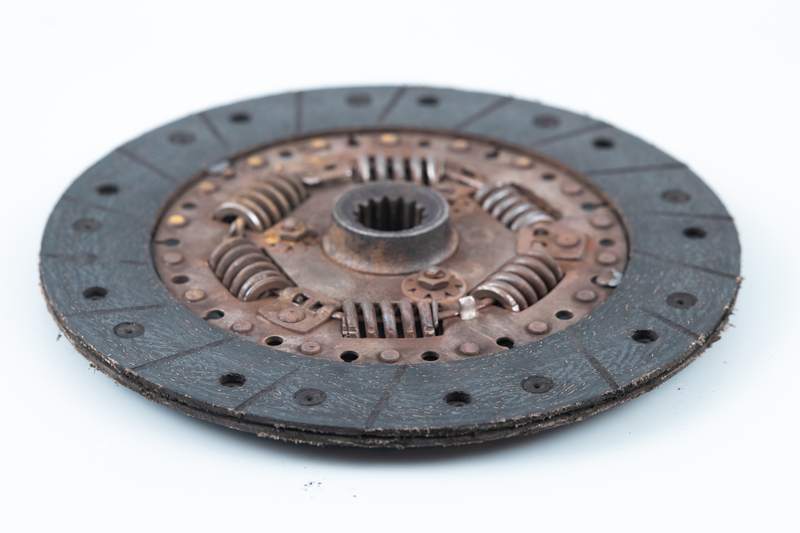

- Clutch Issues

Manual transmissions are common in the John Deere 790, and you may experience issues with how well the clutch engages.

Clutch repairs can be expensive, so it’s a good idea to notice any signs of something wrong. A grinding noise when shifting gears could indicate a loose clutch, which should be inspected as soon as possible to avoid further issues.

- Uneven Mowing Results

The John Deere 790 is equipped with a mower deck, so if you’re having issues with uneven mowing results, it could likely be attributed to the blades or the engine speed.

If the blades are worn or dull, they should be sharpened or replaced. If the engine isn’t running at the correct speed, you may need to adjust the governor as per manufacturer instructions.

- Leaking Hydraulic Fluid

Leaking hydraulic fluid is a common issue with the John Deere 790 and can lead to further issues. Inspect all of the hydraulic lines for any signs of wear or fraying, as this can lead to a leak. If necessary, replace these lines with new ones and check if an oil seal needs replacing.

Make sure you top up the hydraulic reservoir when needed and use only the specified grade of oil. You should also check the hydraulic filter to ensure it isn’t clogged, which can cause a loss of pressure and lead to leakages.

- Improper Fuel Flow

As a John Deere 790 owner, you know how important it is to keep your tractor running smoothly. Unfortunately, improper fuel flow can cause serious issues with the performance of your machine.

If left unchecked, improper fuel flow can lead to engine stalling and poor acceleration.

This can make it difficult to complete basic tasks like mowing or tilling the soil. In addition, incorrect fuel flow may also result in decreased efficiency and increased emissions from the exhaust system.

The good news is that there are ways to fix this problem quickly and easily!

By replacing worn-out parts such as spark plugs and air filters, checking for blockages in the fuel line, or simply adjusting the carburetor settings, you can ensure that your John Deere 790 will be running at peak performance again in no time!

- Ignition System Failures

The ignition system on the John Deere 790 is responsible for supplying the spark that ignites the fuel/air mixture in your engine’s cylinders.

If this system fails, it can cause a complete loss of power and even prevent your tractor from starting altogether. Common causes of ignition system failure include worn-out spark plugs, faulty wiring, or a malfunctioning ignitor.

To troubleshoot ignition system problems on your John Deere 790, you should inspect the spark plugs for signs of damage or wear.

If the spark plugs appear to be in good condition, then it is likely that the issue lies with one of the other components of the ignition system. Replacing faulty wiring or an ignitor should be enough to get your tractor running again, but if not, a more thorough inspection may be required.

- Overheating Issues

It is common for John Deere 790 tractors to overheat when running heavily loaded tasks such as plowing and tilling.

This is usually due to insufficient airflow around the engine, which can cause the temperatures to rise quickly. To prevent this from happening, you should always ensure that the radiator is clean and free of any obstructions.

It is important to regularly check the coolant levels to ensure that your tractor has enough liquid flowing through the system.

If the coolant levels are low, you should top them off as soon as possible to avoid engine damage. Ensure that any hoses or pipes connected to the radiator are in good condition and free of leaks.

- Leaking Fittings

The fittings on your system can lead to plenty of leaking issues over time. While it might not be that serious, you will run into work delays because of this problem.

So, it is best to be proactive and replace any damaged fitting installed in your John Deere 790. This is especially true for owners buying tractors from the second-hand market.

All of these problems have been brought up again and again by several owners. If you’re struggling with any issue not mentioned here, try to call John Deere customer support.

You can also reach out to the dealer, and he will help you through the problem. Hopefully, the issue will be fixed in no time.

How to maintain the John Deere 790 in good working condition?

John Deere’s 790s are powerful and reliable farming machines that require regular attention to ensure they remain in good working condition. By following a simple maintenance schedule, you can ensure the long life of your John Deere 790 and keep it running at its best.

The first step to keeping a John Deere 790 running optimally is to change the engine oil and filter regularly. Make sure to use the correct grade of oil and only use genuine John Deere filters for your model tractor. Check the air filter and clean or replace it as needed.

Checking the fluids regularly is also important for proper operation. Look for potential leaks or signs of wear and tear. Make sure to top off fluid levels as needed, and flush the system when necessary.

It is also important to inspect hoses, belts, and other components for signs of wear or damage. Use genuine John Deere parts specifically designed for your model tractor if a component needs replacement.

By following these simple steps, you can keep your John Deere 790 in good working condition for years to come. Regular maintenance will help extend its life and maximize its value.

I have an early model 790,2000 yr. Which has a mechanical lift pump. I bought the tractor for 1200 dollars because the crankcase was filling with diesel fuel. The mechanical lift pump had a torn diaphram,which emptied into the engine crankcase. I’ll be upgrading to an electrical lift pump with no connection to the crankcase( Like the later models)

I bought a used (1000 hours) 2003 model 790 tractor and have put 200 hours on it. The first failure is the mechanical front wheel drive gears. Although fluids were maintained as per the maintenance manual, the bearings still locked up and stripped the gears out. This is a common occurrence on this model, I am finding out. I’m not a mechanic, but, I’ll be rebuilding the right front wheel gearing this week. Looks complicated, but, it is really just a test of patience and perseverance.