A skid steer is considered one of the most important vehicles for construction and farming. Its incredible weight lifting capacity and efficiency make it a worthwhile investment for farmers and construction workers.

From construction to agriculture and even transportation, skid steers are widely used in various industries. It can be equipped with several attachments to suit different purposes.

With that out of the way, you must have heard about John Deere if you have done some research on skid steers. Based in the USA, John Deere is a well-known corporation that manufactures forestry, agricultural machinery, and other heavy equipment.

It was founded in 1837 and is among the most successful companies in the industry.

John Deere has a wide range of quality skid steers which it provides to the customers. Although they are all known for their durability, the John Deere 320D is particularly popular for its reliability. However, that does not mean that it is immune to problems.

Just like any other heavy machinery, there are certain problems that you may encounter while using this model. So, what are the John Deere 320D problems, and how do you troubleshoot them? That would be the premise of our discussion today.

How to Fix John Deere 320D Problems?

Below are some common John Deere 320D problems, along with their solutions.

- Instrument Panel Issues

Instrument panel issues are quite common in the John Deere 320D skid steer. The John Deere 320D skid steers use the instrument panel to help you operate it better. It boosts your productivity by quickly giving you all the critical information, such as attachment information, functional information, etc.

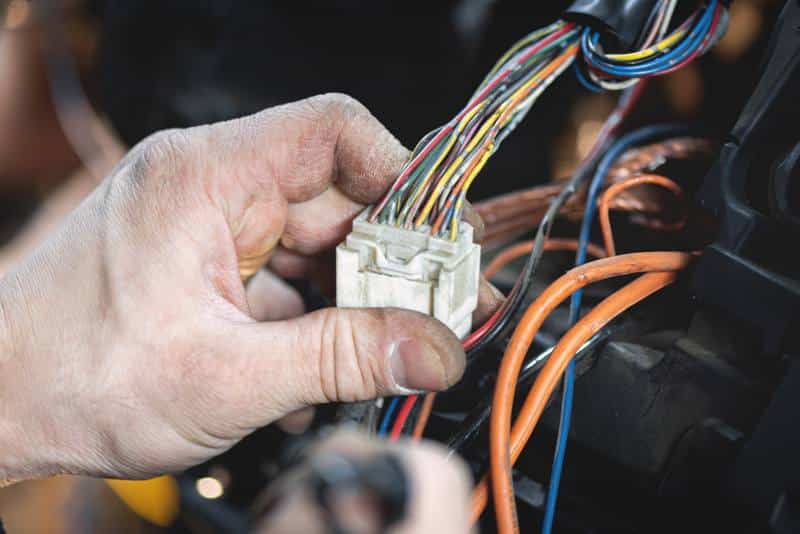

If you have been facing the instrument panel issues, there could be something wrong with your John Deere 320D skid steer wiring. So, start fixing the problem by inspecting the connection wires. If they show any damage, consider making the right adjustments to resolve the issue.

You may also want to have a look at the fuse of your John Deere 320D skid steer. A fuse is a component used in vehicles to protect the electric circuits. In case too much current flows through the circuits, the fuse blows up to ensure your skid steer’s safety.

If blown out, it can cause numerous little problems, including the instrument panel problems. You will need to replace the fuse to restore the instrument panel’s functionality.

If you want to inspect the fuse, you will need to access your John Deere 320D skid steer’s fuse panel. You can refer to the owner manual if you are unsure about its location. And yes, you can also download it online in case you have misplaced it.

Once you have accessed the fuse panel, take a closer look at the fuses to find out whether they are in proper working condition or not. A blown-out fuse can be easily detected as it will have metallic residue on its body. And yes, make sure to buy a fuse with the same amperage rating.

If all the fuses are intact, consider inspecting the wiring clusters. If you see a worn-out wire, replace it immediately and try using the instrument panel. Damaged cables can cause similar problems in the system, and it may take hours to detect the problem.

Frequent wiring problems may damage your instrument panel beyond repair. There have been a few cases where users had to change the entire instrument panel of the John Deere 320D skid steers. So, consider buying quality wires to avoid the headache later on.

If you want to purchase a new instrument panel, make sure to identify the reason for the failure of the last panel. This way, you won’t need to replace your panel again because of the same disorder.

- Issues With Hydraulic Arms

Many users have reported hydraulic arms issues while using the John Deere 320D skid steer. Usually, these issues are related to leaks, pumps, and filters. So, it would be best to start by checking the filters to ensure they are not clogged.

If the performance of your John Deere 320D skid steer has decreased recently, it might be due to clogging in filters or insufficient hydraulic fluid in your skid steer. Overusing the skid steer can also cause this problem.

Hydraulic fluid plays a vital role in the proper operation of the John Deere 320D skid steer. It effectively dissipates the heat and is also responsible for lubricating the internal components. If your skid steer has a low hydraulic fluid level, you may also face overheating issues.

Consider examining the filters first, as it can be done quickly. If you have not changed the filters for months, they might have clogged, causing this problem. If they are fine, you will need to check the hydraulic pump.

If you’re not getting the desired performance even after replacing the filter, look at the pressure in the system and check for possible leaks, especially if your John Deere 320D skid steer has been overheating recently.

And yes, make sure to inspect the engine cooling system to diagnose the reasons for overheating.

In addition to that, make sure to double-check loose fighting and the lines going into the reservoir. Replace any damaged lines or valves and fill up the reservoir to optimal levels.

The fluid leakage also decreases your John Deere 320D skid steer’s performance drastically. So, you will notice a significant hike in its performance as soon as you fix the leakage.

Having said that, if you do not see any leakage, the hydraulic pump may also be the culprit. If so, getting it replaced is the only viable option. However, consider contacting an expert before replacing it to make sure that no other component is causing this problem.

The last thing you’d want is to spend money on the pump replacement just to find out that it wasn’t the problem in the first place.

- Battery Problems

Many users have complained about the battery problems in the John Deere 320D skid steer. Even though this problem might not seem too difficult to deal with, it can be quite annoying when your skid steer’s battery dies midway while working.

To fix this problem, consider checking your battery’s output with a multimeter. If the output is not satisfying, you will have no option but to replace it.

However, if the power output is optimal, check for the corroded terminals and damaged wiring. Most of the time, cleaning the terminals and the connection points fixes battery issues.

Final Thoughts

The John Deere 320D skid steer is known for its high efficiency and durability. However, you may encounter a few problems while using it. The instrument panel may not work smoothly, or the hydraulic system may also show problems.

Consider inspecting the fuse, filters, and hydraulic pump to diagnose the problem. If it seems complex, consider hiring a professional mechanic to get it fixed.