When you want to consider buying a tractor and want better mobility and efficiency, you should buy a skid steer, which is a far better choice. You can find various brands available in the market that have good quality and various skid steer models available.

Many farmers choose to buy models such as John Deere or Bobcat; these two are the most popular. These two brands aim to provide excellent value to their respective customers. However, like with most tools and machines, there are times when you can face the malfunction of these machines.

John Deere is an established brand in the market with many models available, but it has come into notice that customers often face issues with John Deere 317G. Some of the most common issues that are usually complained about in this skid steer model of John Deere.

Most Common John Deere 317G Skid Steer Problems

- Bad Switches

You can face many problems with various switches, such as control switches on the instrument cluster and safety switches; these are the most common minor problems you will encounter in John Deere 317G.

Many people deal with a faulty seat safety switch that cannot be easily fixed and can cause trouble. Some people have pointed out that the skid steer can turn off randomly and frequently as the machine won’t seem to have any power.

The safety button is designed to keep the customers safe from any accidents that may occur with the skid steer. However, at the same time, the safety switch can cause trouble and make the skid steer stop functioning as it should.

In such situations, many people prefer to bypass the safety switch to make the machine start working as it should. Despite such methods used for fixing the problem, these fixes are only temporary and not a full-time solution.

It is strongly recommended that you should get a mechanic to fix the safety switch. It is one of the important functioning buttons of the skid steer, and any minor trouble with this can cause serious damage to the machine or the users.

If you are a beginner, you should avoid bypassing the safety switch by yourself; trouble with the safety switch can be a severe concern for you. When you can call a professional mechanic, they can help you fix this problem long-term, which is a good idea.

You can initially try checking the connection points to see if there is a miss in them, or at times you will find dirt or corrosion on the connection points, which can make the safety switch malfunction and cause your skid steer to stop working.

You can easily clean any dirt or corrosion on the connection points, and you need to ensure that they are thoroughly cleaned; this will help your machine work better and not shut down if you are trying to pick something with it.

- Shutting Down Under Heavy Load

Besides shutting down at frequent intervals, there are other problems with the skid steer; many customers have complained about how the hydraulic system works poorly under load. This is another common issue that the customers have repeatedly complained about.

Customers have mentioned that when they try to lift something heavy with the loader arms, the system suddenly shuts down, and there is no power coming from the hydraulic. This problem can often arise when the reservoir has been overfilled.

If the oil reservoir is filled beyond its capacity, the skid steer will be unable to do any heavy lifting. There is little to no space present to generate pressure from and help with the mobility of the arms of the loader.

If you want a quick fix, you will need to remove any excess oil from the system; this will help stabilize the machine. It is also advised that if you replace the filters on the system regularly, such problems will never occur.

If the filters of your skid steer have not been cleaned or replaced for an extended period, there is a high probability of them getting clogged which can cause trouble generating the internal pressure.

If you can still fix this problem, you should call a mechanic and get your skid steer thoroughly examined. If your machine is under warranty, you can put a claim to your supplier, and there are chances that your supplier will replace the machine. This is a good way to be precautious and save money at your earliest.

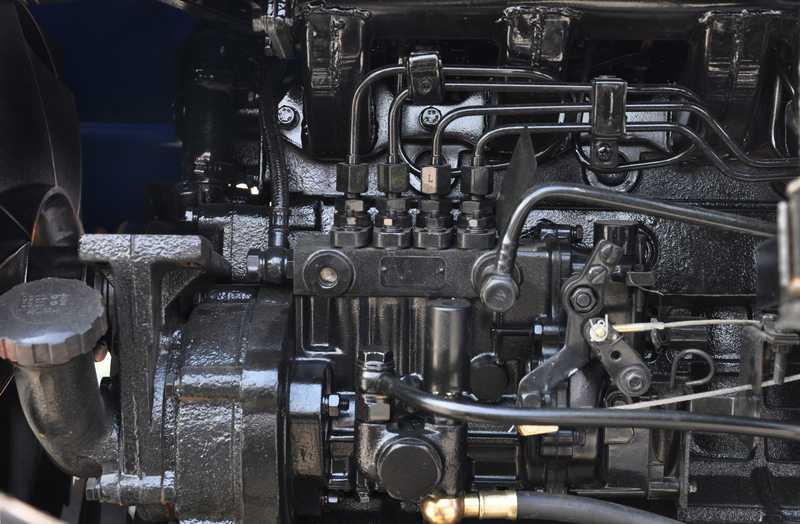

The John Deere 317G can also have engine problems related to the connection points and depending on the quality of fuel used. If you find that your machine is not getting efficiency from fuel in the manner required or you face engine stalling problems, you can try and replace the filter.

The filter replacement is light on the pocket, and you can easily find the replacements. You can also check the fuel line and keep an eye on the overall fuel system to detect any problem at the earliest. Such issues are likely to cause trouble with the engine power of your skid steer.

If your machine starts stopping abruptly or the engine takes longer to start, you should first check all the cables. Ensure that all the cables are perfectly aligned and attached to the power system; check if the connection points are in good condition.

Every machine requires time-to-time checkups and maintenance; if you prolong ensuring the maintenance of your skid steer, such problems are likely to occur more frequently.

If you find yourself unable to start the skid steer, this can be because of a faulty battery. Over time, a machine can have problems with its different parts. If your skid steer has become old, you should consider replacing its battery.

The estimated time for running a battery is usually three years, and after that, your battery can start causing problems. You can start looking to buy a new battery for your skid steer to improve its quality.

Changing or replacing the battery also comes under maintenance as you need to keep an eye on the battery.

Before concluding that your battery has expired, you can check the output levels by using a multimeter on your battery pack. When you use a multimeter, it can detect any problems within the battery, and you can decide whether to replace the battery of your skid steer or not.

Another common issue you can face with your skid steer is a default in the hydraulic system. It can be possible that your skid steer loader isn’t working properly.

This could mean that the hydraulic fluid level is at fault. Ensure that the fluid level isn’t overfilled or underfilled; for a hydraulic system to work the way it should, it needs to have the exact amount of fluid advised by the company.

Like clogged engine fuel, the hydraulic fuel filter can also be clogged, which can directly impact the skid steer’s working. One of the signs that indicate the fluid filter to be clogged is when you notice your loader does not have power like before.

A clogged filter can cause a hindrance for the fluid from flowing easily, which affects the loader’s power. Another common thing you need to check on is the hydraulic system pump; this helps the skid steer work properly.

If the hydraulic pump is a belt-driven model, you can check if the belts are secured and in good condition. If they are not tightly attached or worn out, your hydraulic system will not give good performance.

I HAVE A 318 G SKID STEER THAT WILL NOT LIFT UP UNDER PRESSURE