John Deere is a well-known name in the farming and agriculture industry as they have designed an exceptional range of skid steers and tractors.

John Deere 320 skid steer is one of the best equipment they have designed with a gross horsepower of 69 horsepower and a four-cylinder turbocharged diesel engine, promising high-end functionality. However, some users have been struggling to turn on the skid steer but the problem is quite easy to fix!

Methods to Try When John Deere 320 Skid Steer Won’t Start

- Fix Loose Connection Points

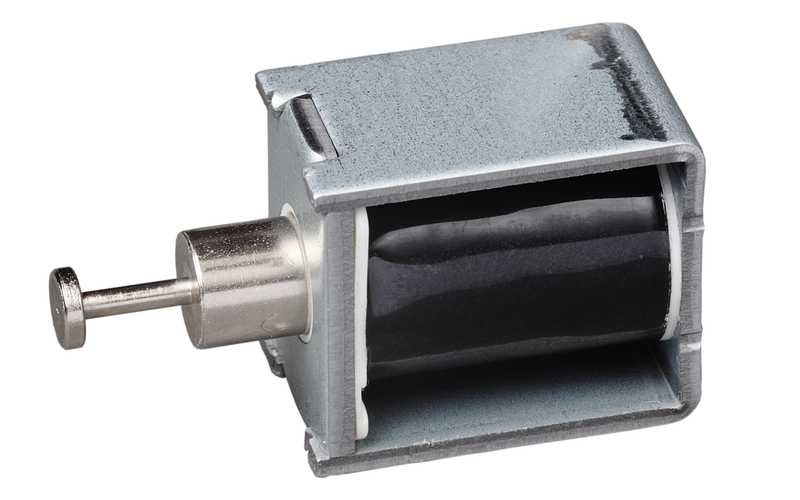

The first solution is to check the connection points because loose connections fail to create a connection with the engine, resulting in functionality errors. For this purpose, you need to trace the cables connected to the starter solenoid and conduct a proper inspection. If the cables are loose, you need to connect them tightly to the solenoid.

The solenoid is responsible for creating a magnetic field and allowing the ignition system to connect with the starter motor. In simpler words, a solenoid is essential for turning on the skid steer, and if the cables are loose, the solenoid won’t be powered up and the skid steer won’t start.

In addition to tightening the cables, you need to ensure that the cables aren’t damaged.

Last but not least, you have to clean the points where cables are connected to the solenoid. You can use alcohol wipes or a diluted vinegar solution to clean all the connection points. Once you’ve cleaned the connection points and the cables are tightly connected to the solenoid, try turning on the skid steer.

- Check Safety Switch

In case the cables and connection points are working normally, there could be something wrong with the safety switch. A safety switch is responsible for preventing the engine startup if it’s not in neutral or park mode.

It eliminates the risk of starting the vehicle in reverse or drive mode. However, when the safety switch is damaged, the transmission and engine system fails to perform.

The safety switch can be accessed from under the seat, and if it’s not in the correct position, the skid steer won’t start. It is recommended that you call a mechanic to fix the safety switch or you can replace it on your own.

Keep in mind that trying to use the skid steer with a bad safety switch can cause permanent damage to the transmission system and engine, so replace it as soon as possible.

- Check Fuses & Relays

If you have been using the John Deere 320 skid steer for a long time, it is better that you inspect the fuses and relays. The fuses are important for protecting the electrical components of the vehicle while relays help protect the users by keeping the high-voltage away from the switches.

So, when the fuses and relays are damaged, the electronic system of the skid steer will stop and the skid steer won’t start.

You can use a multimeter to check the continuity of fuses and relays. If the continuity is less than 50ohms or higher than 120ohms, you need to replace the fuses and relays.

- Replace Battery

A damaged or worn-out battery is another reason why your skid steer is not starting. It is important to check the battery because it provides the electricity that’s needed to use the electric features of the skid steer.

In addition, it transforms the chemical energy into electrical energy that provides voltage to the engine starter. Moreover, it stabilizes the energy supply/voltages to keep the engine running.

You can connect the multimeter with the battery terminals to check the voltage. If the reading is zero, the battery is damaged and needs to be replaced. However, before you replace the battery, try getting it charged or jumpstarted because new batteries can be expensive.

John Deere 320 skid steer uses fuel filters for removing the damaging particulates from the fuel before it reaches the injectors to ensure the smooth functioning of the engine.

In addition, fuel filters promise higher fuel efficiency. However, the fuel filters need regular cleaning and replacement to ensure proper fuel filtration because the particulates can clog the engine, which results in performance issues.

So, if you are having a hard time starting the skid steer, you need to check the fuel filter and clean it. If cleaning doesn’t fix the problem, you will need to replace the fuel filter.

It is better if you choose 10-micron cellulose filters as they prevent the debris from clogging the fuel injectors. However, you can also opt for stainless steel mesh fuel filters if you use methanol fuel in the skid steer.

- Air Filters

An air filter is essential to ensure the free flow of clean air into the skid steer’s engine, making it an essential part of the combustion process. In addition, an air filter prevents the dirt, leaves, and dust from clogging the engine, fuel lines, and injectors.

On the other hand, when the air filter is clogged or damaged, it will restrict the airflow, which slows down or stops the combustion process.

This is because when there is not enough airflow, the engine will not be able to suck enough air into the combustion chamber, which will result in poor performance. Consequently, the skid steer will stop working. For this reason, you need to inspect the air filters and replace them if they are damaged.

- Fuel Pump

The skid steer is integrated with a fuel pump for conveying the fuel from the fuel tank to the engine while optimizing the pressure. So, if the fuel pump is damaged, it won’t be able to pass fuel from the fuel tank to the engine, and the skid steer won’t start.

It is suggested that you hire a mechanic to get the fuel pump repaired or replaced, depending on the damage.

Some other symptoms of failed or damaged fuel pumps include overheated engine, poor engine performance, and inability to sustain the speed. So, you need to check the fuel pump immediately if your skid steer is showing these errors.

The fuel injection pump or an injector pump is responsible for introducing fuel into the engine’s cylinders. It’s a primary component of the diesel engine as it helps maintain the fuel rhythm to ensure smooth operation.

In addition, it controls the fuel flow to achieve a specific power level. However, when the injector pump is clogged or dirty, it results in misfiring and startup errors.

For this reason, you need to hire a mechanic to get the injector pump cleaned. In addition, the injector pump also has a filter that needs to be cleaned because a clogged filter can cause an operational error as well (the engine will crank but won’t start).

- Controls

The hard and foot controls of a skid steer are important for controlling the acceleration and steering functions. In addition, the foot controls are important for controlling the bucket and booms.

However, when these controls are damaged, the skid steer will fail to perform optimally and you won’t be able to switch it on.

So, get the controls replaced by the mechanic to ensure proper control over the skid steer. Keep in mind that these hand and foot controls have rubber bearings that wear out with time and cannot be repaired, which is why a replacement is recommended.

- Glow Plugs

Since this skid steer has a diesel engine, you need to check the glow plugs. The glow plugs are basically the heating elements that consume the battery’s voltage for generating heat, which is important for igniting the fuel during the skid steer startup.

On average, the glow plugs last for 100,000 miles, so if you have surpassed this limit, you need to get the glow plug replaced.

A damaged or worn-out glow plug will fail to ignite the fuel, which means the skid steer won’t start. In addition, it will be challenging to accelerate the skid steer and the engine will start misfiring.

The Bottom Line

The startup issues are common with John Deere 320 skid steer, particularly if you’ve been using it for years. However, the solutions are pretty simple and can be fixed with the help of a professional mechanic.

On the other hand, if the skid steer or its parts are still in warranty, it’s better to call the John Deere technical team for free assistance and repair.

In regards replacing battery on 320D, would be good to add tips on what can be done if battery has totally failed with boom in lowered position. That is, how can old battery be removed from 320D when boom is in lowered position.