Any machine that operates mechanically has many devices scratching against each other. This makes it lose its shape and eventually break away.

This erosion process is extremely fast for machinery moving at a higher speed.

If you do not care for the machine, it will likely break down sooner than expected.

However, the hydraulic system not only provides that lubrication but also creates pressure, which, with the help of pistons, moves the heavier part of the machinery, as in the case of a tractor.

This article discusses how we can check the hydraulic fluid of a tractor.

Do You Check Hydraulic Fluid with The Tractor Running?

The Hydraulic System

As explained earlier, the hydraulic system is the reason we can move the heavier weighted machinery with the slide of a simple lever.

Some tractors use hydraulic pumps to power steering or lift the shovels or buckets. Therefore, it is critical to check the hydraulic fluid in a tractor, and it is important to know how to do it in the first place.

Some tractors have these fluids going through the transmission and collecting in a reservoir.

However, the overall system has dipsticks installed on every tractor, which can be used to determine the fluid level.

Why is it important to check a tractor’s Hydraulic fluid?

Hydraulic fluid is an important part of a tractor’s operation as it helps power the machine’s various components.

A tractor may work correctly or even fail with proper hydraulic fluid levels. Therefore, checking the hydraulic fluid regularly and ensuring all lines are clear and properly connected is important.

The hydraulic fluid in a tractor is the lubricant that allows the various components to move, from the transmission and clutch to the lift arms and loaders.

It also helps to control temperatures, reducing friction between moving parts and dissipating heat from areas prone to overheating.

Hydraulic fluid also helps reduce wear and tear on the tractor’s components, increasing lifespan and performance.

Remove the oil dipstick or cap under the machine’s hood to check a tractor’s hydraulic fluid.

Wipe off any dirt or residue that may have accumulated on the dipstick and reinsert it into the fill port. Remove the dipstick again and check the fluid’s viscosity on its tip.

The ideal viscosity should be between 7-10 CST or centistokes. If the viscosity is too high or too low, add hydraulic fluid to get it within a suitable range.

Check the fluid’s colour to see if it is still a light-amber hue or has changed its colour significantly.

If the fluid appears black, grey or brown, this may indicate that there are contaminants present in the system, which could cause damage in the future.

If the fluid has any noticeable odours or discolorations, it is best to replace the entire system with fresh hydraulic fluid.

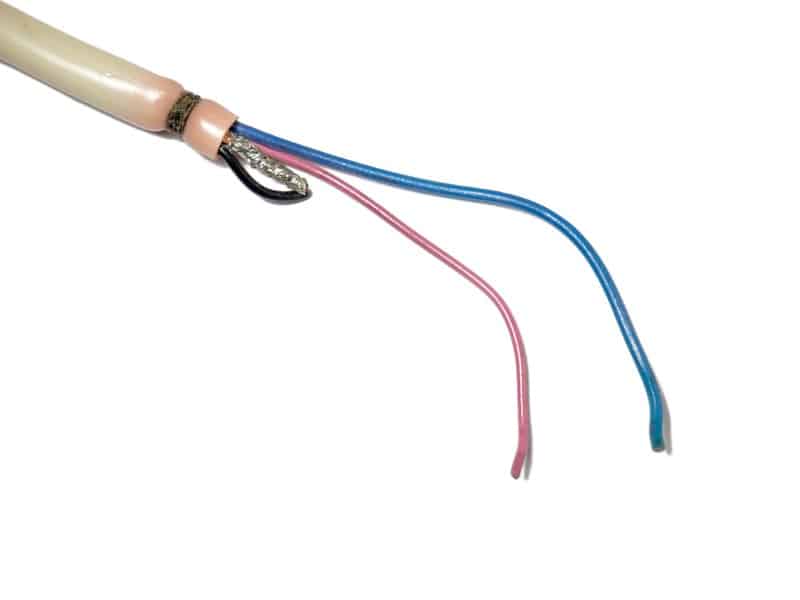

It is also important to check all hoses and fittings connected to the hydraulic system. Look for any signs of wear and tear, such as cracking or bulging, which could result in fluid leakage and a decrease in performance.

It is also important to ensure that the hoses are connected securely and that there are no loose bolts or connections in the system.

Regularly checking your tractor’s hydraulic fluid can ensure optimal performance and reduce the risk of any potential malfunctions or breakdowns.

If you detect any problems with the fluid or hoses, be sure to contact a local mechanic for further assistance. Doing so can save you time, money and hassle in the long run.

Do You Check Hydraulic Fluid With the Tractor Running?

This question is very important to see when starting with checking the hydraulic fluid. A mistake in this might not give you the right results. However, it is easy to check the fluid level.

This ensures that the oil is not extremely hot yet warm enough for a correct reading.

The best way is to see the hydraulic oil reservoir and measure the level. As an optimal level, the line has been etched into the see-through glass.

A lower-than-limit mark that the fluid is less and it needs to be refilled. Otherwise, leave it as it is.

Colour Grading

Different hydraulic fluids have a variety of colours, but they are clear indicators of old and useless hydraulic oil.

Usually, the fluid is clear, and most tractor owners are used to buying this type of fluid.

Nevertheless, companies like the John Deer tractors offer a dyed hydraulic fluid, making it even easier to identify the level of the fluid in the reservoir.

However, if it turns blackish, loses its stickiness, and becomes thinner, then it is best to consider changing the fluids to avoid a failure in the system.

Working in Hydraulics

When the question of do you check hydraulic fluid with the tractor running comes up. It is necessary to educate people on how this works before making a statement.

The hydraulic system uses the force of liquids to transfer force from one point to another using pipes and pistons filled with hydraulic fluid.

When you push a lever or plunger down or pull it, a force or vacuum is created, and the liquid must move to occupy the space or expand to counter the force applied.

This will result either in a contraction or expansion feature in the machine itself.

What happens if you check the hydraulic fluid with the tractor running?

It is not recommended to check the hydraulic fluid with the tractor running, as this can cause dangerous or catastrophic failure of specific components in the system.

The risk of a system component failure due to excessive pressure from running the tractor while checking fluid levels is too high.

Therefore, it is advised to shut off the engine. It is also important to check the manual for specific instructions on how and when to check the hydraulic fluid of your tractor system.

Failing to follow the manufacturer’s instructions can severely damage your tractor. If you are unsure of how to check the hydraulic fluid, it is best to contact a professional service technician for assistance.

What can go wrong when checking for hydraulic fluid?

Hydraulic fluid is a key component of many machines and vehicles, providing the energy needed to run all systems.

Checking for the proper level and condition of hydraulic fluid is essential to keep the system running properly and efficiently.

Despite its importance, several common mistakes can be made when checking the hydraulic fluid.

One of the biggest problems is not changing the fluid regularly. Hydraulic fluid can break down over time, losing its performance and efficiency.

If left unchecked, this can lead to more costly repairs in the future. Dirty or contaminated hydraulic oil can cause decreased performance and accelerated system wear.

To avoid these problems, it is important to check the hydraulic fluid regularly and replace it as needed.

Another mistake is not checking for leaks or other signs of wear and tear in the system.

Leaks can lead to a loss of power, decreased performance and damage to components if left unchecked. Inspecting the system periodically for any signs of leakage and checking the fluid levels often is important.

To avoid unnecessary trouble, ensure you properly dispose of used fluid. Hydraulic fluid that is not disposed of correctly can cause environmental damage or even health risks if it comes into contact with humans.

It’s important to dispose of hydraulic fluid responsibly by either recycling it or transferring it to an approved disposal service.

When checking for hydraulic fluid, it’s important to use the correct type and grade of oil. Different machines and vehicles require different fluids, so select the right one for your system.

Using the wrong type of oil can cause various problems, such as increased wear on components, decreased performance, and even system failure.

Check for any signs of contamination or debris in the hydraulic fluid. Contaminants can prevent proper lubrication and cause reduced performance over time.

Make sure you visually inspect the fluid often for any signs of dirt, sludge or other particles that could indicate a problem.

Common Issues

The level of hydraulic must be maintained, as less fluid will result in lower pressure on the machine parts and eventually result in the machine not moving.

Usually, the oil has been burned away for a lower level of hydraulic fluid and can be fixed by adding new oil to balance out the level.

However, sometimes that level does not remain the same, which means that the cylinders are leaking, the pipelines are cracked, and the oil is seeping out.

This can cause further damage and must be managed and fixed immediately.