Reefers are cargo vans and trucks that include a refrigeration unit in the back to keep temperature-sensitive merchandise cool. Having one of these units installed in machinery or tractors has become a selling point for potential buyers.

John Deere, a multinational firm based in the United States, is known for producing heavy machinery and equipment. The company is well-known as John & Company brand name since it was the goal of two co-owners to begin a business together.

The company’s 180-year history keeps it viable, and it continues to produce cutting-edge technology that improves people’s lives.

The company provides world-class support for its equipment throughout its lifespan, ensuring smooth access to parts, services, and performance improvements from purchase to trade-in, with efficiency and sustainability always in mind!

Innovative and environmentally friendly refrigerants have been installed in their equipment by the company. Their world-class refrigerators keep the temperature stable. It has allowed enjoying the work all year long.

All models have the best-in-class visibility, heating, and air conditioning capabilities, as well as the quietest operating environment in a piece of compact multipurpose equipment such as a tractor.

The cooling system of the John Deer equipment or tractor is maintained by the condenser, compressor, viscous fan drive, cab air filter, and refrigerant. It’s the refrigerant that does the best job out of the rest!

John Deere Refrigerant Capacities

John Deere’s air conditioning system utilizes a refrigerant to capture and recirculate hot air to reduce temperature. As a result, the cabin temperature is lowered by circulating cool air through the air conditioning vents.

Consequently, the cabin is maintained cool and comfortable for the user to sit in on hot or sunny days.

Refrigerant capacity refers to the maximum amount of heat that can be removed from the refrigeration area by the refrigerant. Cooling energy consumption is also included in this definition.

The greater the refrigerator capacity, the better the equipment is! Most John Deere equipment comes with substantial refrigerant capacity.

Chlorine-free John Deere refrigerants are provided since chlorine particles damage the ozone layer. The compressor’s capacity must also be taken into consideration before lodging refrigerant.

We’re talking about a gas refrigerant. If the amount of refrigerant in an air conditioner is sufficient, it will be effective.

If you add too many refrigerants, you risk damaging the compressor. However, if you add only a small amount of refrigerant, the compressor won’t be able to perform its job.

Due to the lack of performance, the air conditioning system will not be at its best. Precautions must be taken when diverting the refrigerant, as it can cause serious injury.

Only R134a (tetrafluoroethane) has been approved for use in John Deere systems. As a refrigerant, tetrafluoroethane is used in making polymeric foams and as a fuel in aerosols, which is an especially useful feature.

R134a is commonly sold in blue cylinders. R134a comes from an HFC (hydrofluorocarbon) refrigerant family. It has no ozone depletion potential and a very low greenhouse gas emission.

Polyalkylene glycol (PAG)-based oil is used for air conditioning in John Deere machinery or tractors. It has been designed to be used with R134a type refrigerants, making it ideal for the John Deere refrigerant.

John Deere has tried using alternative oils, such as Easter oil leads, but it has resulted in poor air conditioning system performance. Due to the experiment of others’ choice of oil, the John Deere equipment/compressor tractors and system degraded and wore down.

John Deere refrigeration compressors and system manufacturers rely on this oil since it meets all their standards. The right type of oil introduced in the John Deere equipment or tractor increases its capacity.

To avoid refrigeration capacity issues, do not combine or dispose of PAG air conditioning oils with waste oil from other internal or external sources, such as motor or transmission oil waste.

The importance of suitable refrigerants with excellent capacities in the John Deere equipment or tractors should have been evident by now. Only good capacity refrigerated equipment or trucks are capable of being a worthy investment!

How does a refrigerant work?

Refrigeration and air conditioning can be achieved using a refrigerant with other components such as compressors and evaporators. Let’s look at how your John Deere equipment or tractor uses refrigerants and the components that regulate it.

- Compressor

The process of refrigeration begins with compression, and a compressor is a piece of machinery used to raise the refrigerant’s pressure. Low-pressure, low-temperature refrigerant enters the compressor; and leaves as the high-pressure, high-temperature refrigerant.

The compressor is powered by the John Deere equipment’s belt drive system and is attached to the engine via a compressor mounting bracket.

- Condenser

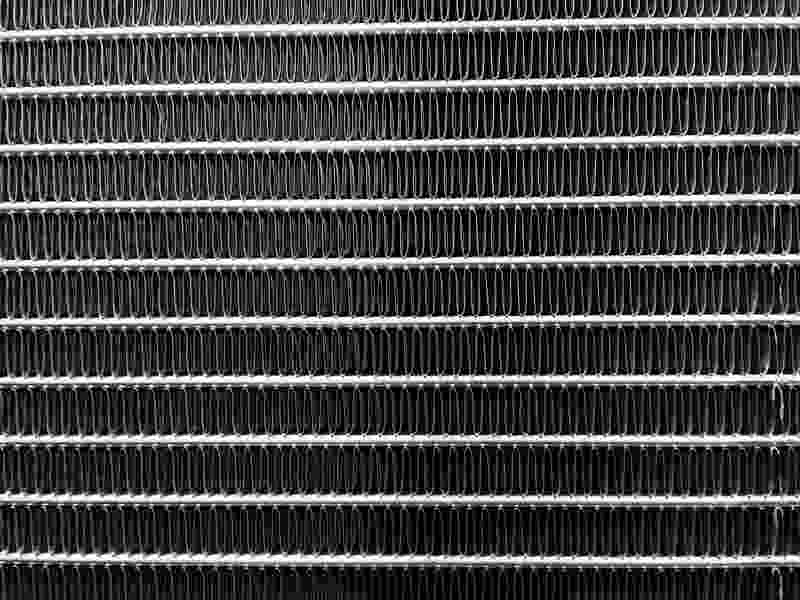

In essential refrigeration, the condenser is one of two heat exchangers. The compressor discharges vaporized, high-temperature, high-pressure refrigerant into this part. After removing the heat from the vaporized refrigerant, it condenses into liquid form, known as condensation.

Cooling the refrigerant by passing it through the condenser coil’s tubes and fins results in a state change. A high-pressure, low-temperature liquid refrigerant is then fed to the loop’s expansion mechanism after it has condensed.

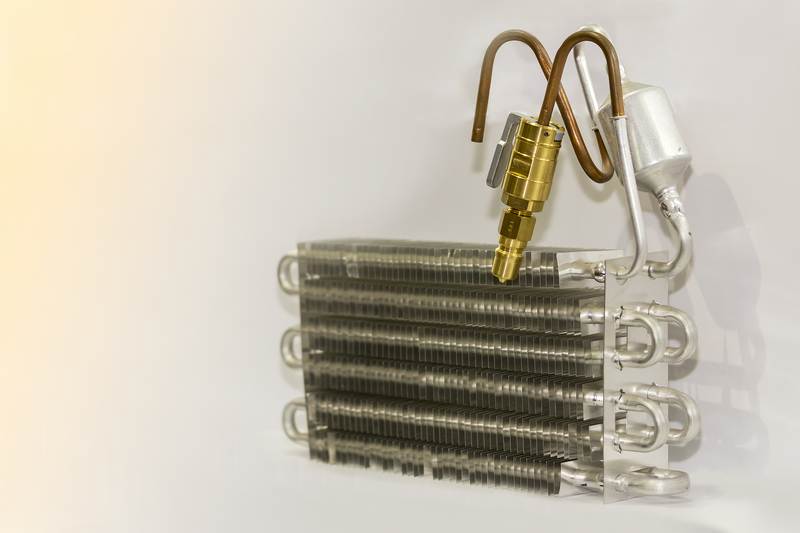

- Evaporator

The evaporator, like the condenser, is the second heat exchanger in a typical refrigeration circuit and gets its name from the process by which it works. We can say that it’s the “business end” of the refrigeration cycle, considering the fact that it absorbs heat.

A fan pushes air across the fins of an evaporator, which cools the air by absorbing heat from the space into the refrigerant. This occurs when low-temperature liquid refrigerant enters the evaporator.

The refrigerated vehicle’s cargo area houses the evaporator. Using a thermostat, the evaporator changes the refrigerant from liquid to gas at low pressure and low temperature as it enters the expansion valve.

To cool the cargo area, a fan-driven evaporator coil collects heat from the air flowing over it.

- Refrigerator

The refrigerant in the evaporator coil is known as a “saturated mixture” because of its high concentration. Low-pressure gas returns to the compressor as a low-temperature gas until the desired temperature is achieved. And that’s the gist of a refrigeration loop.

The Bottom Line

When it comes to air conditioning, the John Deere tractor or equipment’s refrigerant is a core part. The best refrigerant and oil have been employed in this process by the company. As a result, their refrigerant capacitance—the amount of heat they can hold—is quite impressive.

An evaporator, condenser, and compressor work together to lower the temperature along with the refrigerant. John Deere has become a household name thanks to its smooth refrigerating process and use of high-quality refrigerants with adequate capacity.